FFP3 Respirator mask

The FFP3 respirator masks offered by us are tested and evaluated according to the European PPE regulation on the basis of EN 149:2001 A1:2009 for "Particle filtering half masks" by a N.B. (Notified Body) institute or test laboratory approved and certified by the EU.

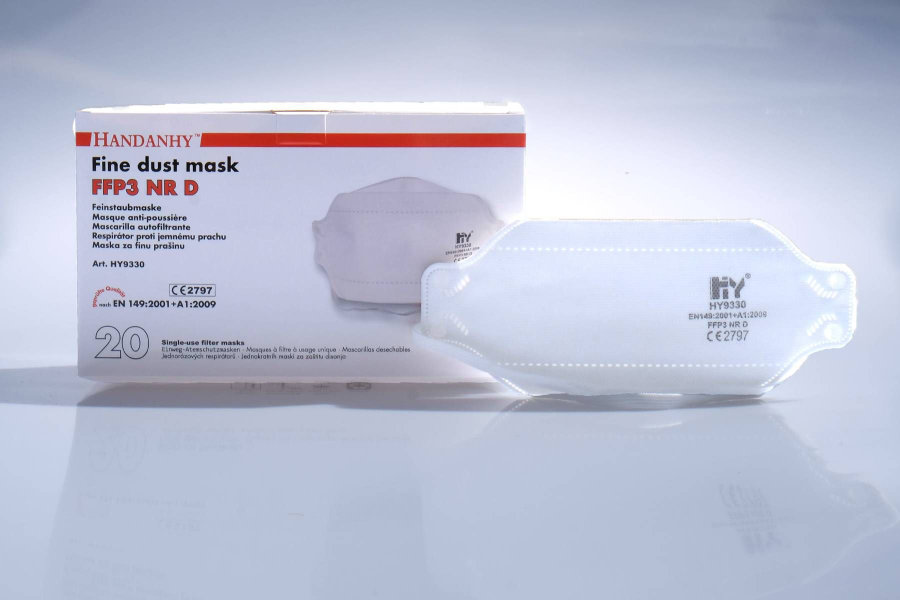

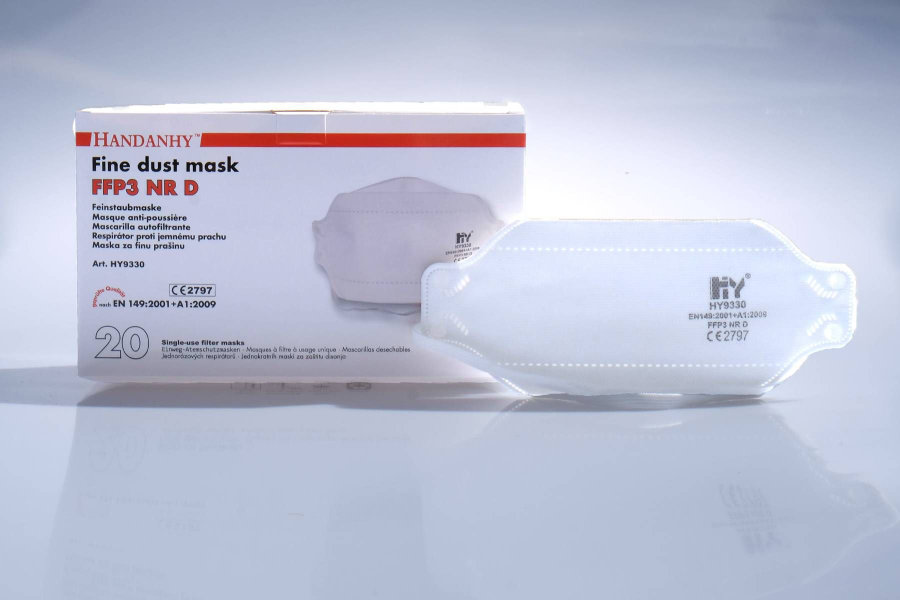

A tested and approved mask can be recognized by the CE mark, followed by the four-digit code number of the testing laboratory (e.g. CE0121) and the mention of the applied standard EN 149: 2001 A1:2009 on the product and packaging.

Requirements for FFP3 respiratory masks

-

FFP3 breathing masks may have a maximum leakage of 5% to the inside.

-

A maximum leakage of 1 % may occur when testing sodium chloride at 95 l/min as a test aerosol.

-

For a paraffin oil test at 95 l/min as a test aerosol, a maximum leakage of 1 % may also occur.

-

The breathing mask must be skin-friendly.

-

The breathing mask must not be highly flammable.

-

The carbon dioxide content of the inhaled air must not exceed an average value of 1.0 % by volume.

-

It must be easy to put the breathing mask on and take it off. The headgear must be adjustable or self-adjusting and must hold the breathing mask in position even under stress.

-

The field of vision must remain clear.

-

The breathing resistance must have a maximum permissible resistance of 1.0 for an inhalation of 30 l/min air.

-

The breathing resistance may have a maximum permissible resistance of 3.0 for an inhalation of 95 l/min air.

-

The breathing resistance may have a maximum permissible resistance of 3.0 at an exhalation of 160 l/min air.

-

The breathing mask must have been tested by a valid testing institute.

Additional requirements for FFP3 breathing masks with valve

In addition to the above requirements, a respirator with a valve must meet the following requirements for the valve of the respirator:

-

If an exhalation valve is provided, it must be protected or resistant to dirt and mechanical damage.

-

The exhalation valves must function correctly in every position.

-

The exhalation valve of a respirator must be protected against dirt and mechanical damage or be resistant. The exhalation valve of a respirator may be encased to allow less permeability.

-

The exhalation valve must continue to function correctly after an exhalation flow of 300 l/min for 30 seconds.

-

When the housing of the exhalation valve is attached to the mask body, it must withstand an axial tensile force of 10 N for 10 seconds.

Labelling requirements for FFP3 respirators

Particle filtering half-masks must be clearly and indelibly marked with the following

-

The name, trademark or other means of identifying the manufacturer or supplier.

-

Type-identical marking.

-

The number and year of publication of this European Standard.

-

The protection class of the respirator, as applicable class (FFP1, FFP2 or FFP3), followed by a single space

-

"NR", if the use of the particle filtering half-mask is limited to only one layer

-

"R" if the particle filtering half-mask is reusable.

FFP3 Information brochure of the manufacturer

Please also check with each order whether the manufacturer has provided an information brochure with the necessary information about:

-

application/limits of use

-

Meaning of each color coding

-

Checks before use

-

Fitting and sealing seat

-

Usage

-

Maintenance for example cleaning, disinfection

-

Information on storage

-

the meaning of all symbols and pictograms used

has enclosed or made available.

Please observe all enclosed instructions for your respiratory protection mask to ensure the best possible protection and handling. Please train untrained personnel and also take a look at our instructions on how to wear a respirator, our manual about correct hand washing and our guidelines about proper coughing and sneezing.